Key Technologies

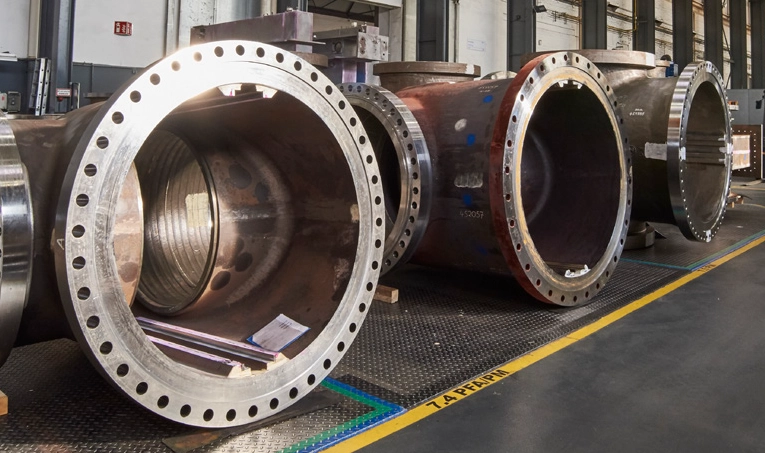

Wedge-within-wedge gate valves

We design wedge-within-wedge gate valves that deliver reliable, first-class performance in extreme operating conditions characterised by high temperatures and pressures, line stresses and a high frequency of operation.

Key Technologies

Fully automatic and safe fractionator isolation valves

The IMI Z&J double disc through conduit gate valve comprises of the very latest technology and has been specifically designed to handle abrasive media under high temperatures. Sizes range from 6” to 100”, and seals are protected in both open and closed positions from erosion.