Enhance your plant’s efficiency

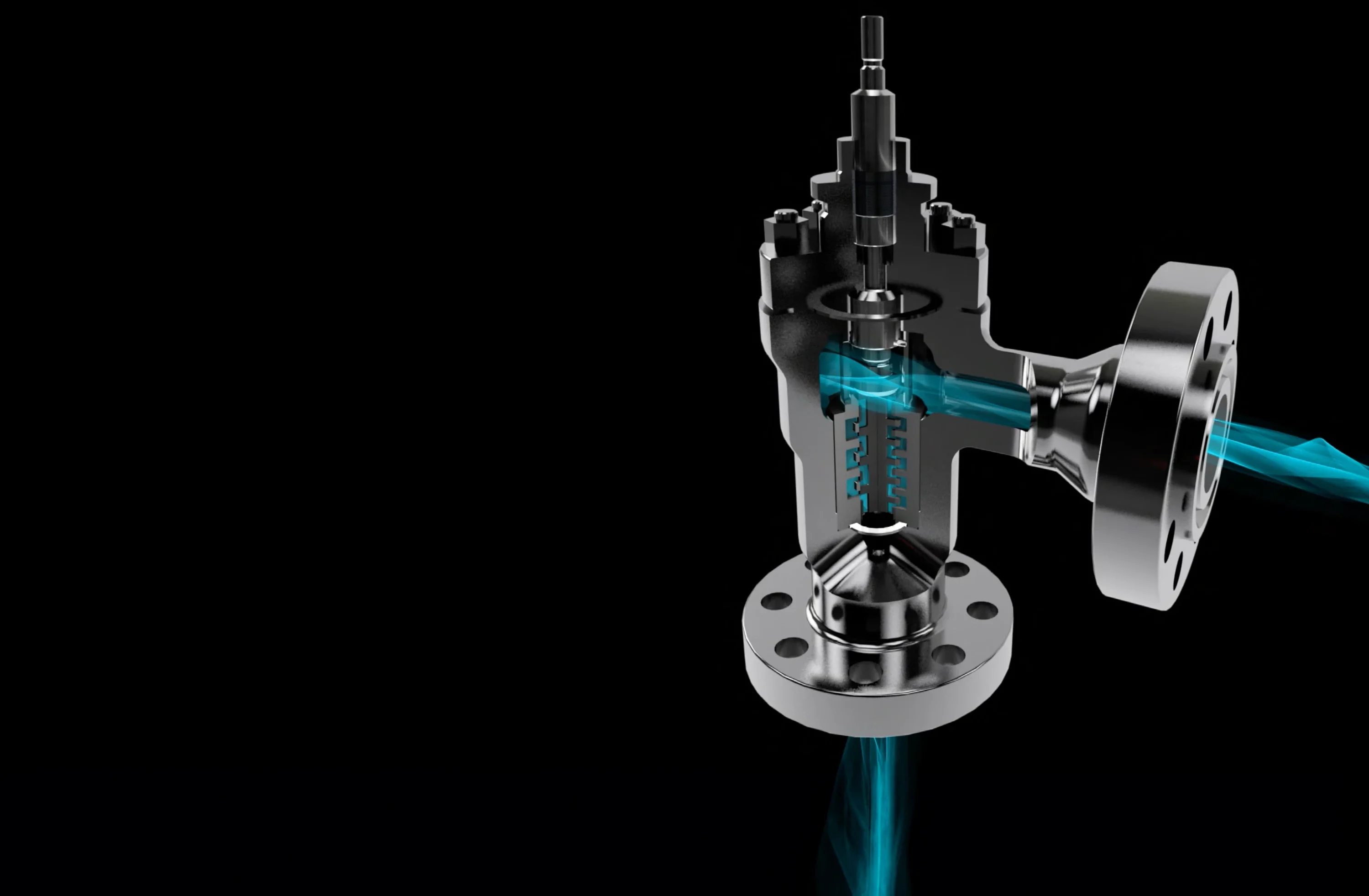

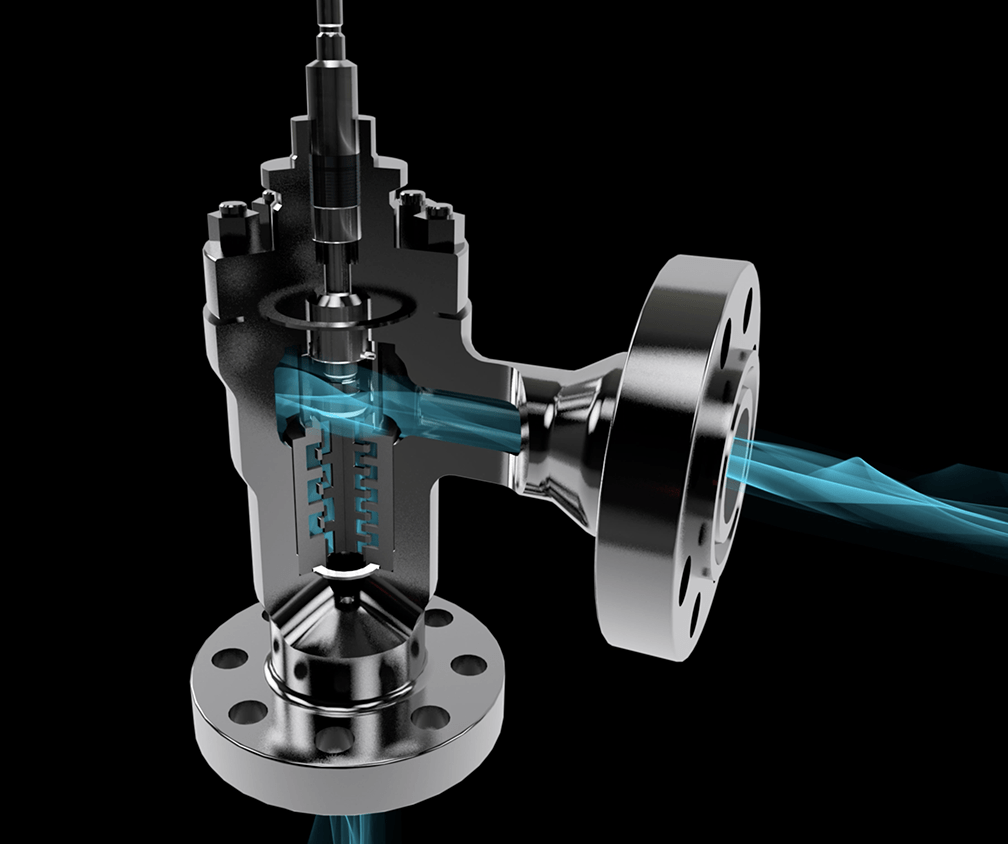

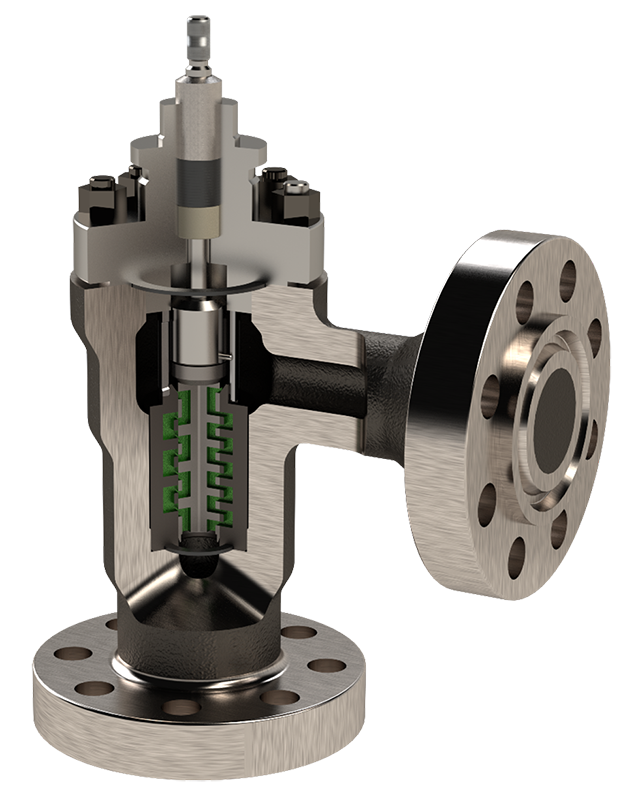

Unlock the full potential of your plant with the EroSolve Metamorphic Trim – a revolutionary self-cleaning solution that combines the benefits of multi-stage labyrinth and cascade technology in a unique design. Our innovative solution is specifically designed to meet the needs of a diverse range of industries, and can help enhance plant safety, boost production efficiency, increase productivity, and drive profitability.

The difference maker

Operators have long faced challenges with minimum flow control, particle contamination, and poor rangeability, which can lead to valve clogging and require split range configurations. IMI’s EroSolve Metamorphic Trim is the solution to these problems. Our innovative trim can upgrade problematic valves to handle challenging operating conditions quickly and easily, with the option for custom designs to fit existing valve bodies and actuators, reducing installation costs.

Performance and reliability in diverse applications

Metamorphic Trim is designed to offer superior performance and reliability in a wide range of industrial applications. From glycol dehydration and amine treatment to slurry pump recycling and desulfurization, our innovative trim is capable of delivering superior control and flow in even the most challenging operating conditions.

- Glycol dehydration

- Amine treatment

- Ammonia letdown

- Steam conditioning spray water

- Feedwater/drum level control

- HP feedwater

- Combined HP feedwater and eco bypass

- OTC feedwater

- High turndown spraywater

- Separator level control and hydro-cyclones

- Pump recycle and discharge

- Level control

- Desulphurisation

- Hydrocracking separator letdown

- MEG injection

- Slurry pump recycle

Experience the benefits

- Utilises multi-stage labyrinth and cascade technologies for improved valve performance.

- Self-cleaning design with expanding passages reduces the risk of clogging and minimises unplanned shutdowns.

- Capable of handling low flow rates and high pressure drops.

- Provides superior rangeability with a single valve solution.

- Features a protected seat design that is not susceptible to damage from cavitation.

- Provides velocity control throughout the trim, reducing the risk of damage and preventing cavitation.

- Eliminates issues caused by gap flow, including control problems and erosion damage.

- Longer maintenance intervals help reduce maintenance and operating costs.

News, blogs and case studies